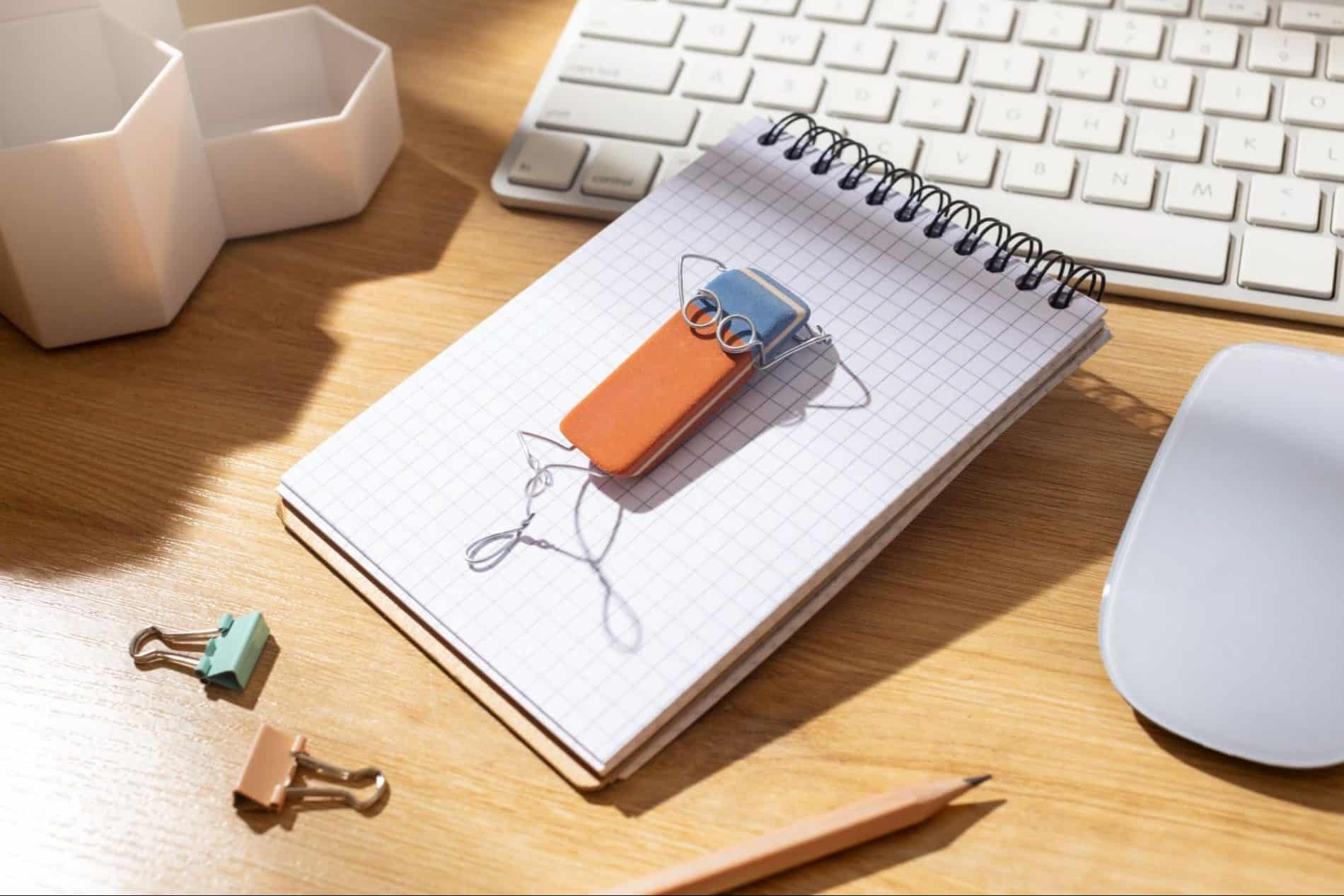

When you make a mistake in pencil, reaching for an eraser is second nature. This humble office and school supply plays a crucial role in our daily tasks, yet how much do we really know about it? In this article, we’ll explore what an eraser is made of, the process of creating one, and the different types available.

The Essential Components of an Eraser

An eraser is typically made up of several ingredients. The primary ingredients include rubber, sulfur, vegetable oil, and pumice. However, the exact composition can vary depending on the type of eraser.

| Primary Ingredient | Function |

|---|---|

| Rubber | Provides the base for the eraser, offering flexibility and durability. |

| Sulfur | Acts as a vulcanizing agent, improving the eraser’s hardness and durability. |

| Vegetable oil | Used as a softener, providing the eraser with a smooth texture. |

| Pumice | Acts as an abrasive, enhancing the eraser’s ability to remove marks. |

Rubber

As the base material, rubber provides the eraser’s core properties. Two types of rubber are commonly used:

- Natural rubber: Derived from the sap of the rubber tree, it’s flexible, resilient, and offers excellent erasing capabilities. However, natural rubber can become sticky or crumbly over time;

- Synthetic rubber: Manufactured from petroleum byproducts, it provides more consistent performance and longevity.

Sulfur

Sulfur is used to vulcanize the rubber, a process that involves heating the rubber with sulfur to create cross-links between the rubber molecules. This makes the eraser more durable and less likely to crumble.

Vegetable Oil

Vegetable oil is used to soften the rubber more pliable. It ensures that the eraser maintains a smooth texture, preventing it from being too harsh on the paper.

Pumice

Pumice, a type of volcanic ash, is included in erasers as an abrasive. It’s this ingredient that helps the eraser remove pencil marks from the paper effectively.

The Making Process of an Eraser

The process of making an eraser is quite straightforward and involves the following steps:

Mixing

In the process of rubber production, one crucial step is mixing the various components to create a uniform mixture. This involves combining rubber, sulfur, vegetable oil, and pumice in a large vat. The ingredients are carefully measured and added to the vat, where they are thoroughly blended until they form a homogenous paste. This mixing stage is vital to ensure that the ingredients are evenly distributed, allowing for consistent quality and performance of the rubber material. The following are some key points regarding the mixing process:

| Aspect | Details |

|---|---|

| Ingredients | Rubber, sulfur, vegetable oil, and pumice |

| Equipment | A large vat or mixer |

| Measurements | Precisely measured according to the desired formulation |

| Mixing time | Continues until a homogenous paste is achieved |

| Homogeneity | Thorough blending ensures even distribution of ingredients |

| Quality control | Regular checks performed during mixing to verify consistency |

| Purpose | Facilitates chemical reactions for vulcanization, enhancing strength and durability of rubber |

Extrusion

After the mixing process, the homogenous paste obtained from the rubber, sulfur, vegetable oil, and pumice mixture undergoes the extrusion stage. This involves passing the mixture through an extruder, a specialized machine designed to shape the material into long, cylindrical rods. The extruder applies pressure and forces the paste through a die, which gives the rubber its desired shape and dimensions. The extrusion process allows for precise control over the final form of the rubber material. Here are some key points about the extrusion stage:

| Aspect | Details |

|---|---|

| Equipment | An extruder machine designed specifically for rubber processing |

| Extrusion process | The homogenous paste is fed into the extruder, where it is heated and forced through a die to shape the rubber into the desired form |

| Die | The die determines the specific shape and dimensions of the extruded rubber |

| Heating and pressure | The extruder applies heat and pressure to soften the rubber mixture and facilitate its passage through the die |

| Versatility | The extrusion process can produce various forms, including rods, tubes, profiles, and more, depending on the die used |

Vulcanization

After the extrusion stage, the long cylindrical rods produced from the rubber mixture undergo a crucial process known as vulcanization. Vulcanization involves subjecting the rubber rods to heat, which triggers chemical reactions within the material, resulting in the hardening and increased durability of the rubber. The rods are typically placed in an oven or heated chamber, where they are exposed to controlled temperatures for a specific duration. During this process, sulfur cross-links the polymer chains in the rubber, transforming it from a soft and pliable material into a resilient and tough one. The following are key points regarding the vulcanization process:

| Aspect | Details |

|---|---|

| Heating method | The rubber rods are subjected to heat in an oven or heated chamber |

| Chemical reactions | The heat initiates sulfur cross-linking of the polymer chains in the rubber |

| Hardening | Vulcanization transforms the rubber from a soft state to a harder, more durable form |

| Durability enhancement | The cross-linking increases the strength, elasticity, and resistance to wear and aging |

| Time and temperature | The vulcanization process involves precise control of time and temperature for optimal results |

Cutting

After the vulcanization process, the long cylindrical rods of rubber are allowed to cool down. Once cooled, they undergo a cutting stage to transform them into individual erasers of the desired lengths. The cooled rubber rods are fed into a cutting machine or a similar tool, where they are precisely sliced into the required sizes. This cutting process ensures the production of individual erasers with consistent dimensions and shapes. Here are some key points regarding the cutting stage:

| Aspect | Details |

|---|---|

| Equipment | Cutting machine or a similar tool |

| Cooling | The vulcanized rubber rods are cooled down before the cutting process begins |

| Precision | The cutting machine ensures precise and accurate cuts to achieve uniform eraser lengths |

| Desired lengths | The rubber rods are cut into individual erasers according to specific length requirements |

| Consistency | Cutting guarantees consistent dimensions and shapes for each eraser |

Quality Control

After the cutting process, each individual eraser undergoes a rigorous quality control inspection. This inspection is crucial to ensure that only erasers of the highest quality are packaged and shipped to retailers. Trained quality control personnel carefully examine each eraser, checking for any defects, such as uneven cuts, surface imperfections, or inconsistencies in shape or size. Erasers that meet the required quality standards are selected for packaging, while any erasers that do not pass the inspection are discarded or sent for further adjustments. Here are some key points regarding the quality control stage:

| Aspect | Details |

|---|---|

| Inspection | Trained quality control personnel carefully examine each eraser |

| Defect detection | The inspection focuses on identifying any defects or imperfections |

| Criteria | The erasers are evaluated against predetermined quality standards |

| Packaging | Erasers that pass the inspection are selected for packaging |

| Discard or adjustment | Erasers that do not meet the quality standards are discarded or sent for further adjustments |

| Shipping | Packaged erasers are then shipped to retailers for distribution |

Different Types of Erasers

There are several types of erasers, each designed for a specific purpose or to work with a particular kind of medium. Here’s a brief overview:

Rubber Erasers

Rubber erasers are widely recognized as the most commonly used type of erasers, specifically designed for removing graphite marks from paper. They are typically rectangular and often colored pink, but they can also be found in different shapes and sizes to cater to individual preferences. These erasers effectively eliminate pencil marks without damaging the paper’s surface, making them a popular choice among students, artists, and professionals. The soft and pliable nature of rubber erasers allows for precise and gentle erasing, enabling users to correct mistakes with ease. Some key features of rubber erasers include:

- Versatile: Rubber erasers are primarily intended for erasing graphite marks but can also be used to remove certain types of colored pencil marks and some ink stains;

- Gentle on Paper: They are designed to erase without causing excessive friction or leaving smudges on the paper, ensuring the integrity of the original document;

- Easy to Handle: The rectangular shape of rubber erasers provides a comfortable grip and allows for controlled erasing, making it convenient for detailed work;

- Long-Lasting: These erasers are known for their durability and ability to withstand extended use before needing replacement;

- Affordable: Rubber erasers are widely available and tend to be cost-effective, making them accessible to a broad range of users.

Vinyl Erasers

Vinyl erasers, also referred to as plastic erasers, are a type of eraser that differs from rubber erasers in terms of toughness and abrasiveness. They are particularly effective for erasing ink or darker pencil marks due to their more abrasive nature. While rubber erasers are known for their gentle and precise erasing, vinyl erasers provide a more robust and thorough erasing action. These erasers are often white and rectangular in shape, although variations in size and form are available. Some key characteristics of vinyl erasers include:

- Ink Erasing Power: Vinyl erasers excel at erasing ink marks, making them a preferred choice for correcting mistakes made with pens or markers. They are also efficient at removing darker pencil marks that may be more resistant to traditional erasers;

- Durability: Compared to rubber erasers, vinyl erasers are generally more durable and long-lasting. They can withstand more extensive use before wearing down or losing effectiveness;

- Abrasive Action: Vinyl erasers have a slightly rougher surface than rubber erasers, allowing for more aggressive erasing. However, caution must be exercised when using them on delicate or thin paper to avoid potential damage;

- Smudging: While vinyl erasers are efficient at removing marks, they may occasionally leave behind smudges, particularly when used on graphite or softer pencil leads. It is advisable to test them on a small area before erasing larger sections;

- Versatility: In addition to ink and dark pencil marks, vinyl erasers can also effectively erase colored pencil marks, charcoal, and pastel markings.

Kneaded Erasers

Kneaded erasers are unique erasers that offer a pliable and moldable texture, allowing users to shape them according to their needs. Artists frequently utilize kneaded erasers to lighten or entirely remove charcoal, pastel, or graphite marks. Unlike rubber or vinyl erasers, kneaded erasers do not leave behind eraser debris, making them ideal for delicate artwork. Here are some key features of kneaded erasers:

- Malleability: Kneaded erasers have a soft and pliable consistency, allowing artists to shape them into various forms like balls, cones, or points. This adaptability enables precise erasing and selective removal of marks;

- Gentle Erasing: These erasers gently lift off the medium from the paper’s surface, making them well-suited for delicate or textured materials like charcoal and pastels. They can also lighten graphite drawings without damaging the paper;

- No Residue: Kneaded erasers do not generate eraser crumbs or residue like traditional erasers. Instead, they absorb and “pick up” the medium, keeping the working area clean and minimizing smudging;

- Longevity: Kneaded erasers can be used repeatedly by kneading and stretching them to expose fresh surfaces. This feature extends their lifespan, making them a cost-effective choice for artists;

- Blending Tool: Apart from erasing, kneaded erasers can also be used as a versatile blending tool. Artists can mold them into soft edges or smooth gradients, achieving unique artistic effects.

Gum Erasers

Gum erasers are a type of eraser known for their softness and gentle erasing action, making them particularly suitable for fine papers and delicate surfaces. They are less abrasive compared to other erasers, ensuring minimal damage or smudging. When used, gum erasers tend to crumble as they erase, effectively absorbing graphite or pencil marks and leaving the paper clean. Here are some key characteristics of gum erasers:

- Softness: Gum erasers have a soft and pliable texture, allowing for smooth and gentle erasing without causing unwanted paper damage. This makes them an excellent choice for thin or delicate papers, such as tracing paper or vellum;

- Non-Abrasive: Unlike some other erasers, gum erasers have a low level of abrasiveness, which reduces the risk of creating marks or indentations on the paper surface. They offer a more forgiving erasing experience, particularly when working on sensitive materials;

- Minimal Residue: Gum erasers tend to crumble and break apart as they erase, effectively absorbing the graphite or pencil marks. This characteristic helps keep the paper clean and prevents smudging or spreading of eraser debris;

- Versatility: While gum erasers are commonly used for erasing graphite or pencil marks, they can also be effective in removing certain types of ink, especially if the ink has not completely dried or has a certain level of solubility;

- Limited Lifespan: Due to their crumbling nature, gum erasers tend to wear down more quickly compared to other erasers. The regular replacement may be necessary to ensure optimal erasing performance.

Electric Erasers

Electric erasers are mechanized tools specifically designed for precision erasing. They feature a spinning eraser tip powered by electricity, which allows for controlled and accurate erasing in detailed areas. Architects and artists, who often require precise and intricate erasing, commonly favor electric erasers. Here are some key features of electric erasers:

- Precision Erasing: Electric erasers offer exceptional precision, allowing users to erase fine lines, small areas, or intricate details with ease. The spinning eraser tip provides controlled and targeted erasing, making them invaluable for architectural drawings, technical illustrations, and other intricate artwork;

- Powered Performance: These erasers are battery-operated or come with an electrical cord for power supply. The motorized mechanism ensures consistent and efficient erasing, reducing the effort and time required for erasing compared to manual erasers;

- Versatility: Electric erasers can be used for erasing various media, including graphite, charcoal, colored pencils, and even certain types of ink. They provide versatility in erasing different materials without causing excessive damage or smudging;

- Eraser Refills: Electric erasers often come with replaceable eraser refills, allowing users to easily swap out erasers when they become worn or depleted. This feature ensures a continued supply of fresh erasers for uninterrupted use;

- Ergonomic Design: Many electric erasers are designed with comfort and ease of use in mind. They often feature ergonomic handles or grips, allowing for prolonged erasing sessions without strain or fatigue.

Conclusion

The humble eraser is a marvel of simplicity and function. By understanding its materials and making process, we gain a deeper appreciation for this everyday tool. Whether you’re a student, artist, or professional, there’s an eraser out there perfectly suited to meet your needs.